Manufacturer of Broken Tool detector Device

Manufacturer of Broken Tool detector Device

Why Inspectool

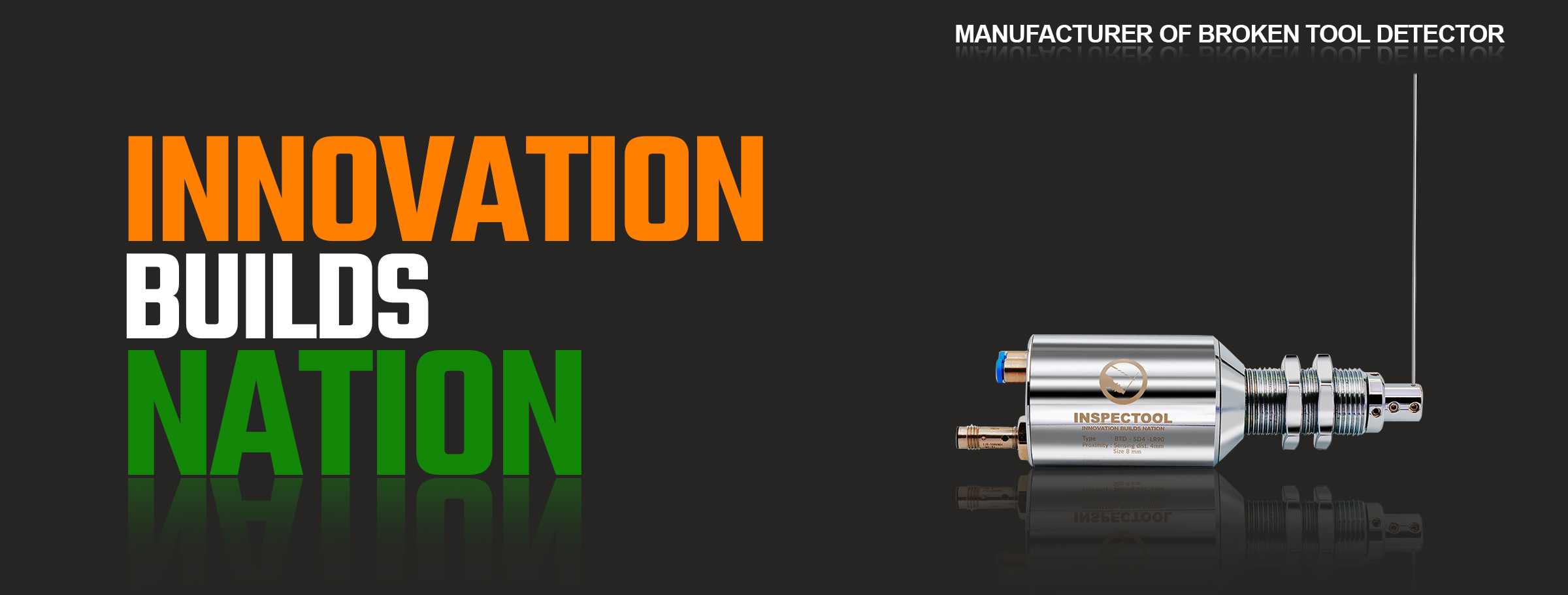

Searching for Broken Tool Detector? Our INSPECTOOL Broken Tool Detector is the world’s first proximity sensor based electro-pneumatic Broken Tool Detector Device. Also, it is world’s cheapest, long lived, robust, and high quality performance Electronic-controller less Broken Tool Detector device.

Quality issues and rejection of parts due to broken drill, tap and reamer are major costly problems that can be eliminated by Broken Tool Detector device.

Quick Start

HOW THE BROKEN TOOL DETECTOR WORKS

INSPECTOOL Broken Tool Detector detects the normal tool or broken tool just by conforming to the rotating angle of a needle. The INSPECTOOL Broken Tool Detector is actuated by compressed air energy that causes rotary motion of the needle in 90 degrees if a tool is broken and results in generation of an input signal to stop a machining operation.

Model Information

With the use of model BTD — SD4 — LR90, the shaft along with the

needle of the broken tool detector can rotate 90 degrees in both

clockwise (CW) and counterclockwise (CCW) directions by interchanging

the pneumatic tubes of application ports A1 and A2